Technology

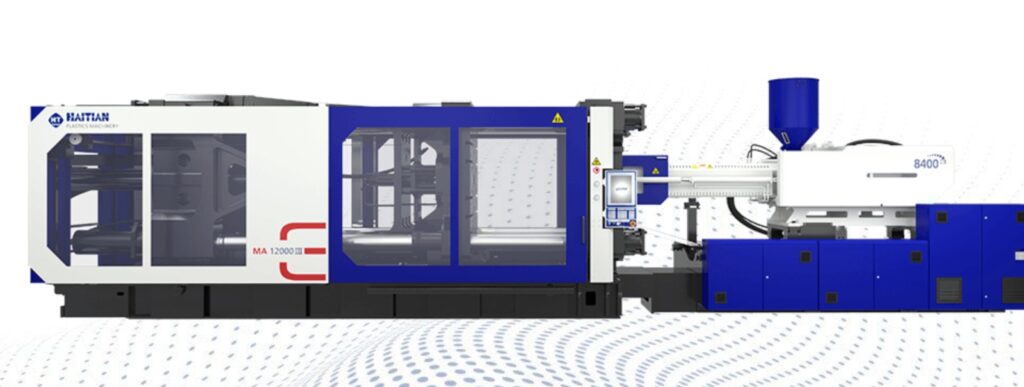

Injection Moulding Machine Technology

Introduction

Injection moulding is a versatile and widely used manufacturing process that creates complex parts and products by injecting molten material into a mould. This technology is essential for industries ranging from automotive to consumer goods.

How It Works

- Material Preparation: Thermoplastic or thermosetting polymers are fed into the injection moulding machine.

- Melting: The material is heated to a molten state in a barrel.

- Injection: The molten material is injected into a precisely designed mould under high pressure.

- Cooling: The material cools and solidifies inside the mould.

- Ejection: The finished part is ejected from the mould.

Key Components

- Injection Unit: Melts and injects the material.

- Clamping Unit: Holds the mould in place and provides the clamping force.

- Mold: The cavity where the material takes shape.

- Control System: Manages the machine’s operations and settings.

Advantages

- High Efficiency: Rapid production cycles and consistent part quality.

- Complex Geometries: Ability to create intricate shapes and designs.

- Material Versatility: Suitable for a wide range of polymers and composites.

- Low Waste: Precise control over material use and minimal waste.

Applications

- Automotive Parts: Engine components, dashboards, and trims.

- Consumer Goods: Household items, toys, and electronic housings.

- Medical Devices: Components for medical instruments and packaging.

- Industrial Components: Gears, housings, and machinery parts.

Recent Innovations

- Advanced Materials: New polymers and composites for better performance.

- Smart Molding Technologies: Integration of IoT and automation for enhanced control.

- Energy Efficiency: Improved processes and machines to reduce energy consumption.

Extrusion Blow Moulding Machine Technology

Introduction

Extrusion Blow Moulding (EBM) is a popular process for manufacturing hollow plastic parts. It involves extruding a continuous tube of molten plastic and then blowing it into a mould. This technology is widely used for creating containers, bottles, and other hollow shapes with high precision and efficiency.

How It Works

- Material Extrusion: Plastic pellets are fed into an extruder, melting and forming into a continuous parison (a hollow tube of molten plastic).

- Blowing: The parison is transferred to a mould cavity, where it is inflated with compressed air to conform to the mould’s shape.

- Cooling: The blown plastic cools and solidifies inside the mould.

- Ejection: The finished product is removed from the mould.

Key Components

- Extruder: Melts and forms the plastic into a parison.

- Mold: Shapes the parison into the final product.

- Blow Pin: Injects air to expand the parison inside the mold.

- Control System: Manages the extrusion, blowing, and cooling processes.

Advantages

- Versatility: Can produce various shapes and sizes, including complex geometries.

- Efficiency: High-speed production with minimal material waste.

- Consistency: Uniform wall thickness and quality in finished products.

- Cost-Effectiveness: Lower tool and material costs compared to other molding processes.

Applications

- Packaging: Bottles, jars, and containers for food, beverages, and chemicals.

- Automotive: Air ducts, reservoirs, and other hollow components.

- Consumer Goods: Household items like toys and other plastic products.

- Industrial: Tanks, bins, and enclosures.

Recent Innovations

- Advanced Materials: New resins and additives to enhance performance and durability.

- Automation: Integrating robotics and smart technology for increased precision and reduced labour costs.

- Energy Efficiency: Improvements in machine design and processes to lower energy consumption.

- Environmental Considerations: Enhanced recycling capabilities and reduced material waste.

Injection Stretch Blow Moulding Machine Technology

Introduction

Injection Stretch Blow Moulding (ISBM) is an advanced manufacturing process used to produce high-quality, lightweight, and strong plastic containers, particularly bottles. The technology combines injection molding and stretch blow molding to create products with superior strength and clarity.

How It Works

- Injection Molding: A preform (a small, test-tube-like piece) is created by injecting molten plastic into a mold. This preform has a thick wall and is designed for subsequent stretching and blowing.

- Stretching: The preform is heated and then mechanically stretched in the axial direction, which aligns the molecular structure of the plastic.

- Blowing: The stretched preform is placed into a blow mold where it is inflated with compressed air. The air pressure forces the plastic to conform to the mold’s shape, producing the final product.

- Cooling: The molded container is cooled and solidified inside the blow mold.

- Ejection: The finished product is ejected from the mold.

Key Components

- Injection Unit: Forms the preform by injecting molten plastic into the mold.

- Stretching Mechanism: Mechanically stretches the preform in the axial direction.

- Blow Molding Unit: Inflates the preform to create the final shape.

- Mold: Defines the shape and dimensions of the final product.

- Control System: Manages the injection, stretching, blowing, and cooling processes.

Advantages

- Enhanced Strength: The stretching process aligns the plastic molecules, resulting in stronger and more impact-resistant containers.

- Improved Clarity: The technology produces containers with excellent optical clarity and surface finish.

- Lightweight Design: Allows for the production of lightweight containers without compromising strength.

- Versatility: Suitable for a wide range of container shapes and sizes, including complex geometries.

Applications

- Beverages: Bottles for water, soft drinks, and juices.

- Food Packaging: Jars and containers for food products.

- Personal Care: Bottles for cosmetics, lotions, and shampoos.

- Pharmaceuticals: Containers for medical and pharmaceutical products.

- Industrial: Containers and bottles for chemicals and other industrial applications.

Recent Innovations

- Advanced Materials: Use of new polymers and additives for enhanced performance and sustainability.

- Automation: Integration of robotics and automated systems for increased precision and efficiency.

- Energy Efficiency: Improvements in machine design and processes to reduce energy consumption.

- Recycling: Enhanced processes and materials for better recycling and environmental impact.

Aluminium Power Press Machine for ROPP Caps

Introduction

Aluminium Power Press Machines for ROPP (Roll-On Pilfer Proof) caps are essential for the manufacturing of high-quality, tamper-evident closures used in a variety of industries. These machines offer precision and efficiency in producing caps that ensure product integrity and safety.

How It Works

- Material Preparation: Aluminium coils are fed into the press machine. These coils are typically pre-coated or treated to enhance performance.

- Stamping: The machine uses a high-pressure stamping mechanism to form the aluminium into the shape of the ROPP cap. The process involves pressing the aluminium into a die to create the cap’s structure.

- Forming: Additional operations may include embossing, forming, or trimming to achieve the final cap design and ensure a perfect fit on the bottle.

- Inspection: Caps are inspected for quality, including checks for defects and consistency in dimensions.

Key Components

- Press Mechanism: The core component that applies the force needed to stamp and form the aluminium.

- Die Set: Custom moulds that shape the aluminium into the desired cap form.

- Feed System: Mechanism for loading and advancing the aluminium coils.

- Control System: Manages the press operation, including timing, pressure, and automated functions.

- Ejection System: Removes the finished caps from the die and prepares them for further processing or packaging.

Advantages

- High Precision: Produces ROPP caps with precise dimensions and consistent quality.

- Efficiency: Capable of high-speed production with minimal waste.

- Durability: Ensures the production of strong, tamper-evident closures that enhance product security.

- Flexibility: Can be adjusted for various cap sizes and designs, accommodating different bottle types and applications.

Applications

- Beverages: Caps for bottles of soft drinks, water, and other beverages.

- Pharmaceuticals: Tamper-evident caps for pharmaceutical and health products.

- Food Products: ROPP caps for food containers and sauces.

- Cosmetics: Caps for bottles of lotions, creams, and other personal care products.

- Chemicals: Caps for chemical containers that require secure and reliable closures.

Recent Innovations

- Enhanced Automation: Integration of advanced robotics and automation for increased production speed and precision.

- Smart Controls: Advanced control systems for better monitoring and optimising the pressing process.

- Material Advancements: Development of new aluminium alloys and coatings to improve cap performance and sustainability.

- Energy Efficiency: Innovations in machine design to reduce energy consumption and operational costs.